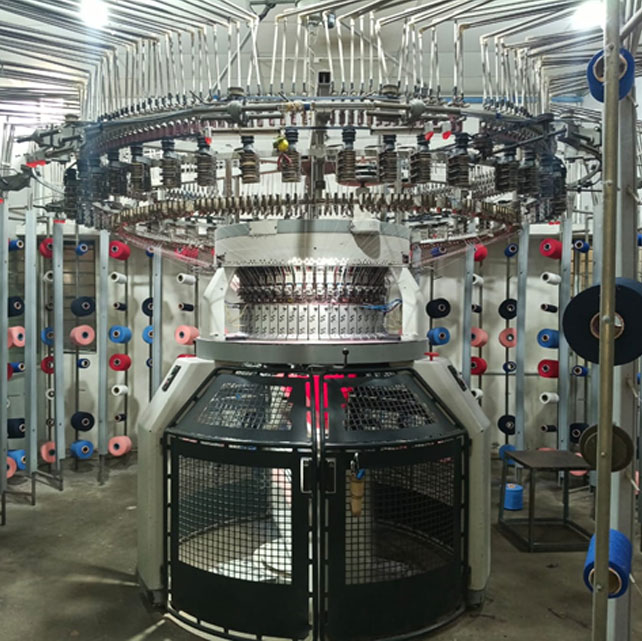

KGS Textiles utilizes the latest and advanced technology machineries to knit the fabrics like Reiter, Mayer & Cie to produce various qualities of circular knitted fabrics right from 100gsm to 400gsm.

Ultra modern soft flow machines are used for fabric dyeing. Dyes and chemicals used are azo free as per Oeko Tex standards and. HTHP machines used for cotton, polyester, Viscose and other blend fabrics.

Technically advanced machinary to bring up a high level of dimensional stability and enhanced quality. Designed for ease of Operation and maintenance.

All over print using rotary printing machine Stormac for reactive, pigment, discharge & Placement prints. pigment, plastic sol, non pvc, flock, glitter, discharge prints on machines like Hebbecker & MHM.

Computerised multi head embroidery machines to make chain, loop stitch and chenneli designs up to 8-9 colors on Japanese make Barudan machine. Hand embroidery designs with sequence work, beads…Stone fixing, rhime stones, heat transfer photo & flock prints.

Our cutting department ensures precision and efficiency — from fabric spreading, pattern marking, and defect inspection to accurate cutting, numbering, and bundling, all aimed at minimizing wastage and maintaining top quality for every garment

Garment sewing unit is done with proper lighting, good floor space and amenities. Legal and statutory norms with respect to social systems and physical facilities are provided. As a safety standard we are following necessary covid 19 precautions.

Checking is to trim all extra threads and also checks for stains and holes. All garments are 100% checked before packing. In the checking section the pieces are properly checked by efficient people.

Automated ironing lines work in tandem to ensure smooth ironing of all the products. This line also serves as a final quality checkpoint before the products are packed.

We buy our packing materials from leading suppliers and professional providers. We use Oeko Tex certified labels and tags produced from the certified suppliers.